The Future of Industrial Efficiency: How Flexible Hose Connectors Are Revolutionizing Business Operations

Introduction

In the ever-evolving industrial landscape, efficiency, durability, and adaptability are paramount. One often-overlooked component that plays a crucial role in optimizing fluid transport systems are the flexible hose connectors. These connectors are essential for industries relying on fluid, gas, or material conveyance, offering enhanced flexibility, durability, and performance.

As companies across Europe embrace new technologies, the role of flexible hose connectors in improving operational efficiency has gained significant attention. In this article, we delve deep into the world of flexible hose connectors, their benefits, applications, and the technological advancements shaping the industry.

Understanding Flexible Hose Connectors

Flexible hose connectors are crucial components in industrial applications where pipelines require adaptability, vibration absorption, and reliable fluid transfer. These connectors are designed to withstand pressure variations, temperature fluctuations, and mechanical stress while maintaining a secure connection.

Key Features:

- Material Versatility: Available in rubber, stainless steel, PTFE, and composite materials to suit different industrial applications.

- Pressure & Temperature Resistance: Designed to handle extreme temperatures and high-pressure conditions.

- Flexibility & Vibration Absorption: Reduces stress on connected components, enhancing the lifespan of the system.

- Corrosion & Chemical Resistance: Essential for industries dealing with aggressive fluids or harsh environments.

- Compliance with Industry Standards: Many flexible hose connectors adhere to ISO, EN, and other international safety and quality regulations.

Industries Benefiting from Flexible Hose Connectors

1. Manufacturing & Automation

In automated production lines, flexible hose connectors facilitate the seamless transport of liquids, gases, and granular materials. These connectors help in:

- Enhancing machine movement without causing stress on pipelines.

- Reducing maintenance costs due to fewer breakages.

- Allowing easy reconfiguration of production layouts.

2. Chemical & Pharmaceutical Sectors

Handling aggressive chemicals requires connectors that resist corrosion and degradation. Flexible hose connectors in these industries ensure:

- Safe and efficient fluid transfer.

- Reduced risk of leaks that could lead to contamination.

- Compliance with stringent regulatory requirements.

3. Oil & Gas Industry

The oil and gas sector operates under extreme conditions, making durable and pressure-resistant flexible hose connectors indispensable. They play a role in:

- Offshore drilling platforms where flexibility is essential.

- Absorbing vibrations in pumping systems.

- Transporting crude oil, gas, and refined products safely.

4. Food & Beverage Processing

In food-grade applications, flexible hose connectors ensure hygiene and compliance with food safety standards. They are commonly used for:

- Transferring dairy, beverages, and processed foods.

- Maintaining sterility with smooth, easy-to-clean internal surfaces.

- Eliminating the risk of contamination in sensitive processes.

5. HVAC & Building Infrastructure

Heating, ventilation, and air conditioning (HVAC) systems rely on flexible hose connectors for:

- Efficient fluid and gas flow in piping systems.

- Minimizing noise and vibration in buildings.

- Facilitating quick installations in complex setups.

Technological Advancements in Flexible Hose Connectors

As industries continue to push boundaries, modern flexible hose connectors are incorporating advanced technologies for better performance.

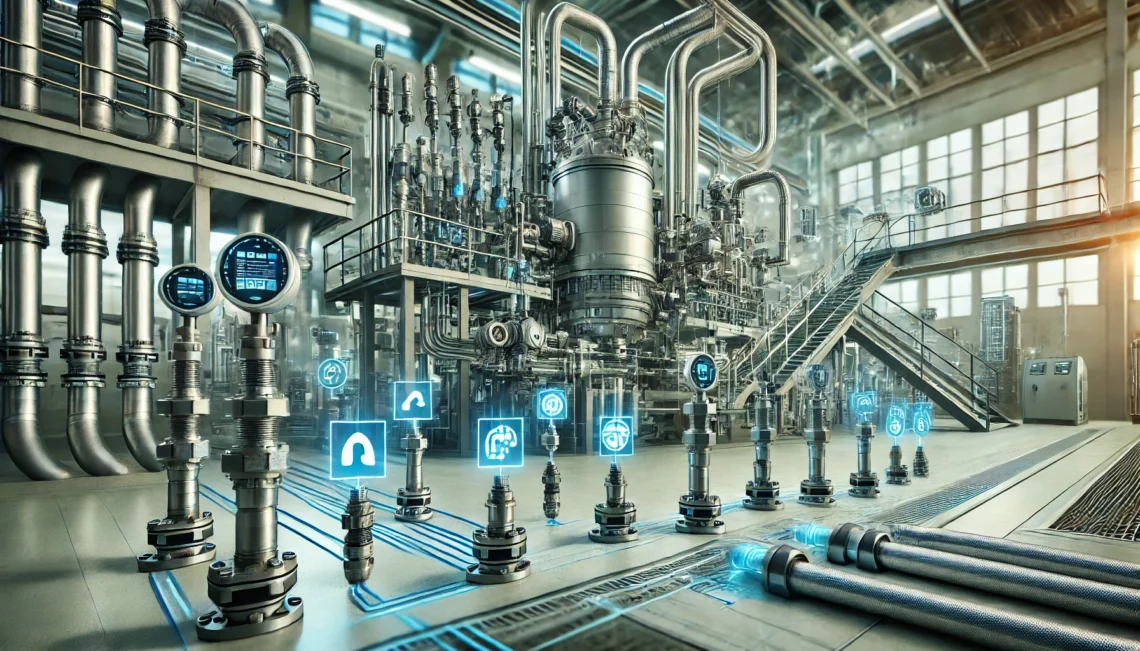

1. Smart Monitoring & IoT Integration

With the rise of the Industrial Internet of Things (IIoT), some flexible hose connectors now come equipped with sensors that monitor:

- Pressure variations.

- Fluid flow rates.

- Leak detection alerts. These innovations allow predictive maintenance, reducing downtime and operational costs.

2. Advanced Materials for Longevity

New developments in material science have led to the creation of hoses with enhanced:

- Thermal resistance.

- Chemical compatibility.

- Reinforcement layers for extreme durability.

3. Customization & Modular Designs

Flexible hose connectors now come in customizable designs to fit specific industrial needs. Modular components make replacements and upgrades easier, reducing downtime during maintenance.

Choosing the Right Flexible Hose Connector

Selecting the right connector depends on several factors, including:

- Application: Identifying whether the hose will transport gases, liquids, or solids.

- Temperature Range: Ensuring compatibility with the operating environment.

- Pressure Ratings: Choosing a hose that can withstand the required pressure levels.

- Material Compatibility: Selecting a hose resistant to the fluids being transported.

- Regulatory Compliance: Meeting industry standards and certifications.

Common Materials and Their Applications

| Material | Applications |

|---|---|

| Stainless Steel | High-pressure, temperature-sensitive environments, oil & gas |

| PTFE | Chemical processing, food, and pharmaceuticals |

| Rubber | General industry, automotive, and HVAC |

| Composite | Lightweight, high-flexibility applications |

Sustainability & Environmental Considerations

Sustainability is a growing concern for European businesses. Flexible hose connectors contribute to eco-friendly operations by:

- Reducing Energy Consumption: Efficient fluid transport minimizes energy waste.

- Enhancing System Longevity: Reduces waste from frequent replacements.

- Using Recyclable Materials: Some modern connectors are designed with recyclability in mind.

- Minimizing Leakage & Contamination: Preventing hazardous spills and fluid losses.

The Future of Flexible Hose Connectors in Industry

Looking ahead, businesses adopting innovative hose connector solutions will benefit from increased efficiency, reliability, and sustainability. Trends to watch include:

- Increased Automation: Integration with robotic systems for dynamic industrial applications.

- Enhanced Safety Features: Development of self-sealing or rupture-resistant hoses.

- More Sustainable Materials: Eco-friendly, biodegradable alternatives.

Companies investing in the latest flexible hose connector technologies will gain a competitive edge in industrial efficiency and cost savings.

Conclusion

Flexible hose connectors may seem like a small component in large-scale industrial operations, but their impact is undeniable. By ensuring flexibility, durability, and performance in fluid and gas transport, they contribute significantly to industrial productivity.

For companies looking to optimize their infrastructure, choosing the right flexible hose connector can mean the difference between costly downtime and seamless operations. With technological advancements and sustainability initiatives driving innovation, the future of flexible hose connectors is set to redefine industrial standards across Europe.